Standardized IQC inspection

workflow independent area

ERP system control

auto 3D SPI tin cream tester

silk printing real-time surveillance

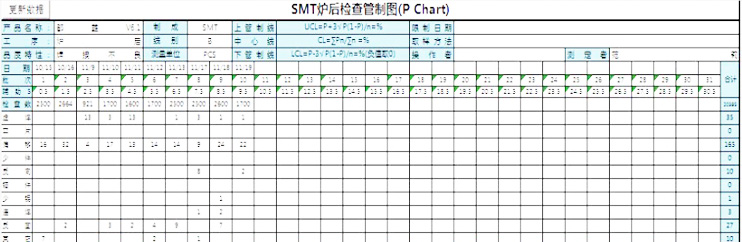

SPC data collection

每班次加工生产的第一个工件或加工过程中因换人、换料、换岗以及换工装、调整设备等改变工序条件后加工的第一个工件,其首件产品由IPQC检验合格后交由生产部方可进行批量生产;品质部IPQC将确认结果记录于《首件确认记录表》

material tracing system,

lot number management to ensure every single material is trackable

Scanner in production line to prevent material misidentification

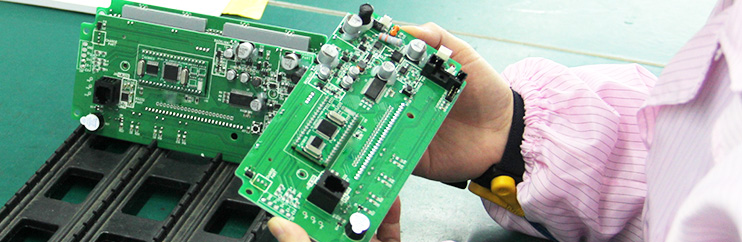

Standardized destaticization

Periodic inspection with static detectors

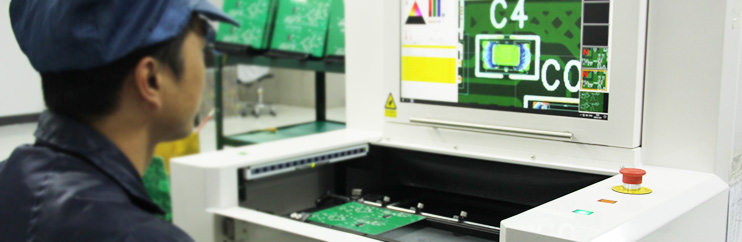

AOI inspection to avoid component defect as excursion,misidentification,deletion,reversion,inadequate soldering,etc

SPC data help to accurately identify the abnormal value to achieve better control

Complete FCT & ICT test according to different customer requirement

Appearance inspection before delivery